MOZLASER Laser Cleaning Machine

Laser cleaning machine is another high-end application of laser technology development, compared to the traditional chemical cleaning, mechanical grinding, ultrasonic cleaning, dry ice cleaning Laser cleaning machine has the following characteristics.

- Non-touch cleaning, No demage to the base material

- Non-polluting, no need for any cleaning chemicals

- High cleaning cleanliness and high speed efficiency

- Requires only electricity, no other special consumables

- Wide range of applications, metal and non-metal can be cleaned

- Handheld operation, simple process,no experience required for operators

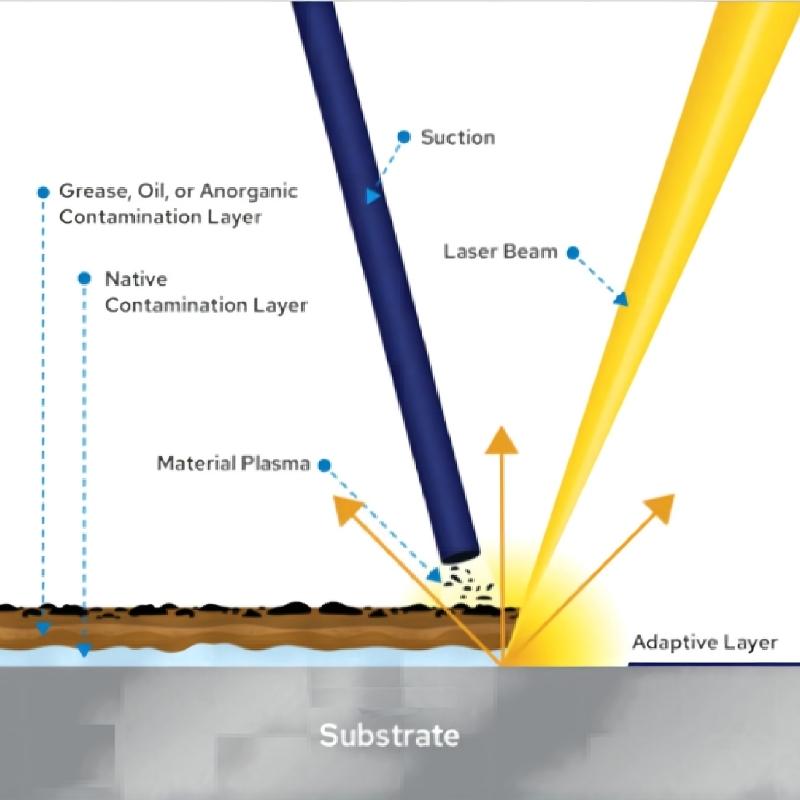

How Does the Laser Cleaning Machine Work?

Laser cleaning is the use of high-energy laser beam irradiates the surface of the workpiece to be cleaned, through vaporization, ablation, shock waves, thermal elasticity and other effects will be removed from the surface of the workpiece pollutants. The cleaning process without cleaning mediators, can avoid the traditional cleaning of serious substrate damage (particle cleaning), mediators residue (chemical cleaning) and other issues, the damage to the substrate to an acceptable range.

Laser cleaning machine principle diagram

The Machine Catagory

Mini volume design,built-in 100W pulsed laser source and 1100W battery pack,you can take it to anywhere for working.

Portable laser cleaning machine, with an air cooling system, light weight design whole volume is smaller than a 22″ luggage case.

200W pulsed fiber laser power, 8 type of cleaning modes,reinforced the universal wheel on the basis of 100W.

300W pulsed fiber laser power, industrial grade universal wheel,sturdy and easy for you to move around your workshop.

Medium 500W pulsed fiber laser power,8 type of cleaning modes, excellent inset water cooling system.

1000W high power pulsed fiber laser , 1000W for CW laser is common,but pulsed laser it’s a such high power.

Laser Cleaning Applications (12)

Moz Guarantee

The whole machine 2 years warranty,exclude consumables

After-sale service guaranteed response and solution within 24 hours

Provide free parts for replacement within the machine warranty period.

If in the service area, our engineers or partners provide on-site installation.

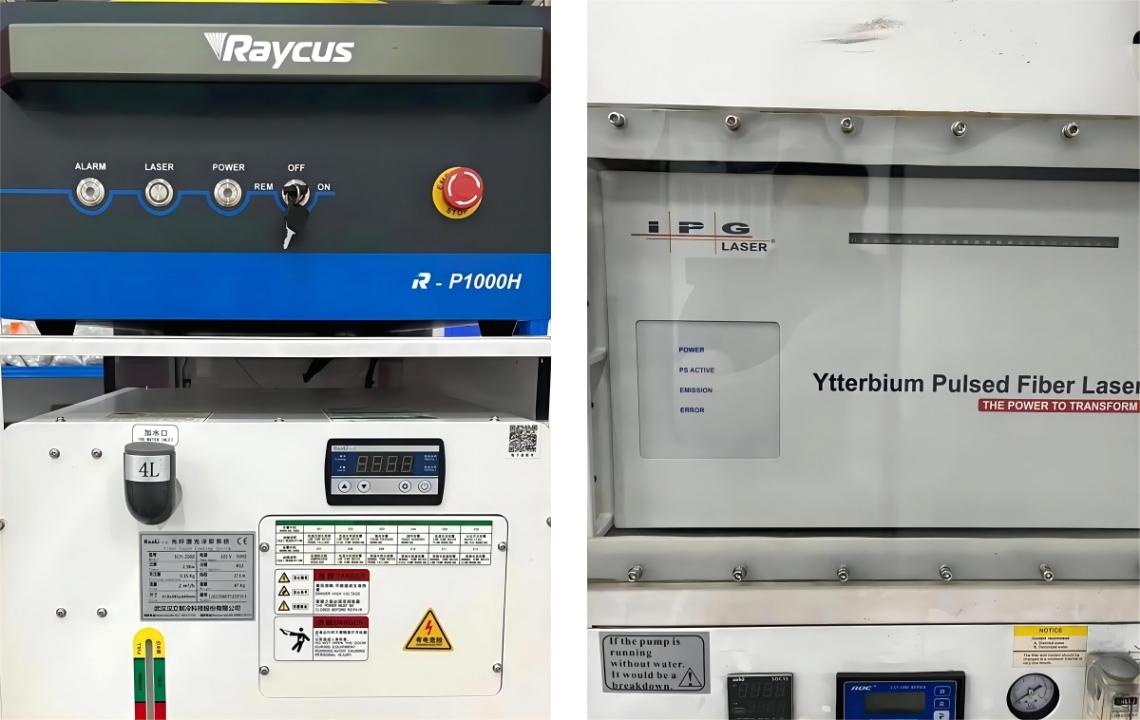

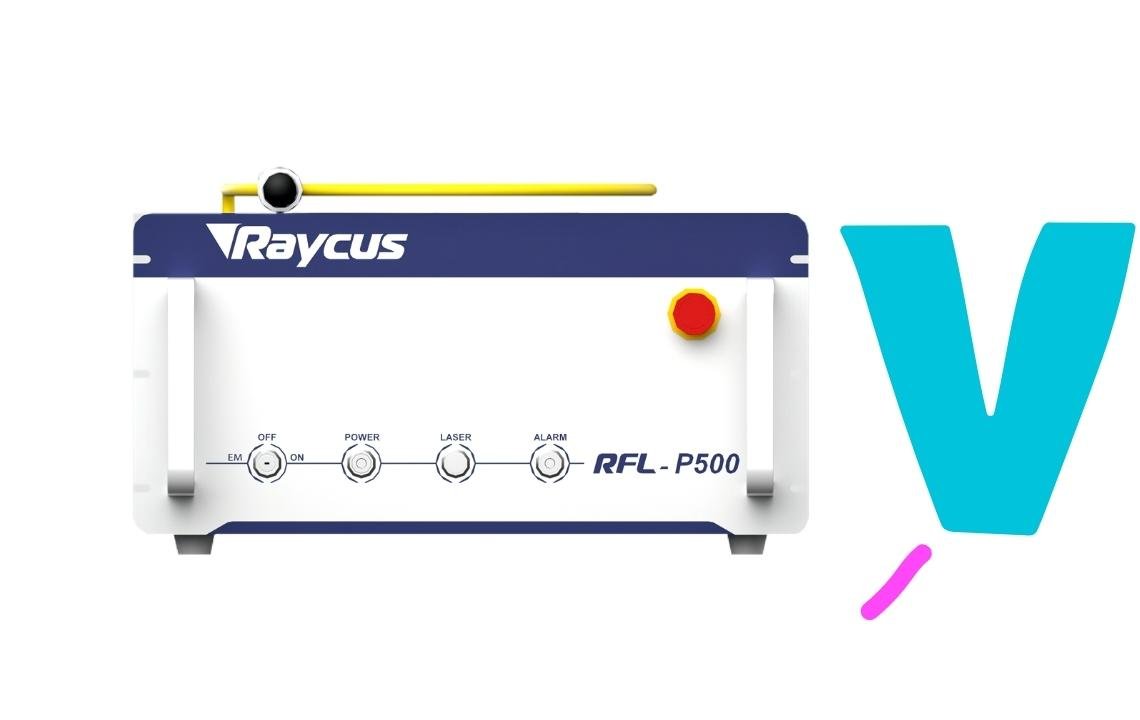

Raycus P Series Pulsed Fiber Laser Souce

This pulsed laser source have nanosecond level pulse width, different from continuous fiber lasers, nanosecond pulsed laser single pulse energy is huge, and the pulse width is narrow, the peak power is extremely high.

So when the laser cleaning machine’s laser beam contact cleaning objects, the surface organic dirt layer absorbs the laser strongly, the temperature of the organic dirt layer quickly rise to the evaporation point vaporization, so as to achieve the purpose of removing the contamination layer without damaging the substrate.

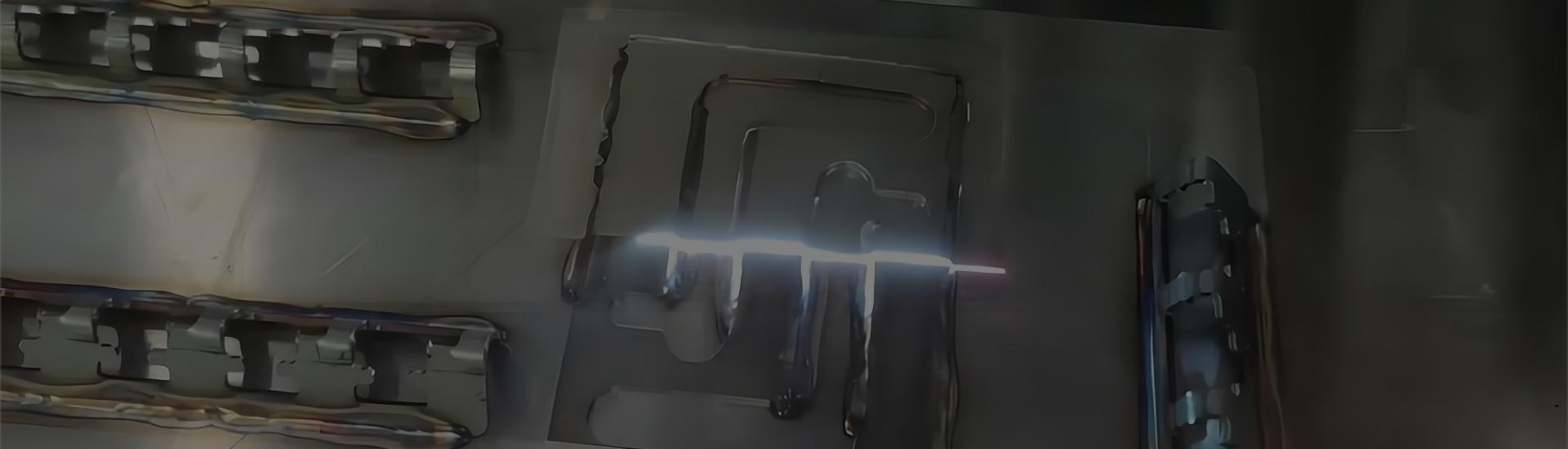

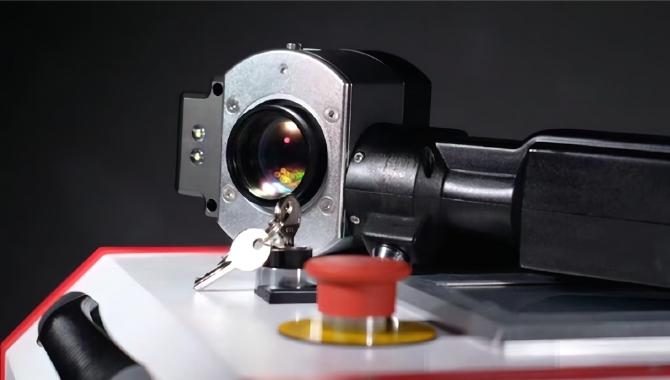

Exclusive 4th Generation Scanning Laser Cleaning Head

MOZLASER laser cleaning machine use exclusive 4th generation scanning laser cleaning head, the laser head has an independent cooling module to quickly cool down and stabilize the laser cleaning process, the laser head supports handheld mode and automatic scanning cleaning dual mode, eight scanning modes, different shapes to cope with different cleaning scenarios.

The laser cleaning head also has an integrated security lock and lighting to ensure the safety of use, and can cope with the dark environment.

Laser Cleaning System with Touching Screen Panel

Advanced multi-threaded multi-port laser cleaning machine control board and panel, customizable language and cleaning graphics, machine users can test their own cleaning parameters and save memories for self-selection and easy access to parameters according to different materials.

For any customization of cleaning graphics and parameters, please contact us for sample and parameters testing.

What is the difference between pulsed laser cleaning machine and continuous laser cleaning machine?

The biggest difference between the two kinds laser cleaning machines comes from the working mode of the laser beam, pulsed laser is pulsed out of the laser mode, the peak power is very high, 200W laser can reach 60KW laser peak, pulse width also reached the nanosecond level, can quickly vaporize the surface organic layer, almost no damage to the substrate. Continuous laser for continuous laser mode, will continue to heat the cleaning surface, you can achieve the purpose of cleaning but also damage the substrate.

Pulsed laser source allow better control of heat input and prevent excessive substrate temperatures or micro melting. But continuous laser source have an advantage in price and can bridge the gap in efficiency with pulsed lasers by using high power lasers, but the heat input of high power continuous laser is more huge and can cause more damage to the substrate.

Application scenarios with high precision, requiring strict control of substrate temperature rise and requiring no damage to the substrate, such as molds, engine parts,are recommended to choose pulsed lasers. For some large steel structures, pipes, steel plate etc., due to the large volume of heat dissipation fast, the substrate damage requirements are not high, then you can choose continuous lasers.

Focus on the Customer Use Experience

MOZLASER laser cleaning machine aimed at different customers cleaning scenarios, developed a multi-shape cleaning mode, standard eight cleaning modes, such as line, rectangle, spiral line, circle filling, etc, and also accept special cleaning mode customization, please communicate with us in detail before you place an order.

As we always say, we have a good relationship with many of laser brands, so except for Raycus Lasers , you can also choose from IPG Photoics ,Max Photonics,JPT Lasers. Each brand has its own advantages in a certain field, such as the stability of the laser, price, after-sales service, etc. Please contact us to clarify your concerns.

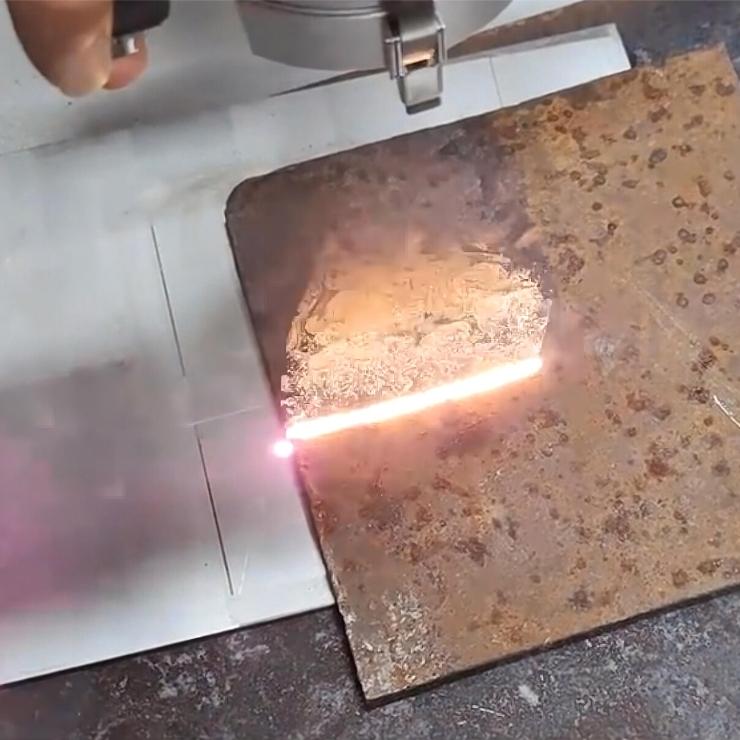

Some Application Scenarios for Pulsed Laser Cleaning Machine

Railroads, high-speed rail, part of the subway rail in the open air environment, through the sun and rain, the surface will produce rust and dirt accumulation, if not cleaned for a long time, seriously affect the rail circuit, affecting the railroad signal transmission, endangering train safety, the traditional method is to use manual grinding rust removal, very low efficiency, labor intensity is too large, and easy to damage the rail, laser cleaning machine is the new century of high-tech applications, cleaning Rail labor cost is low, no special consumables, environmental protection, no pollution, good cleaning quality, and does not damage the rail base material.

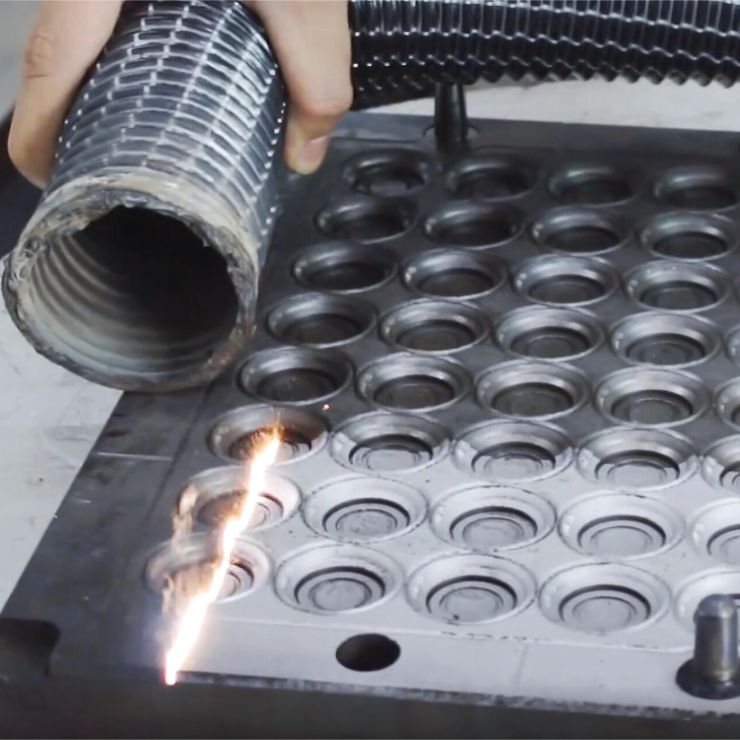

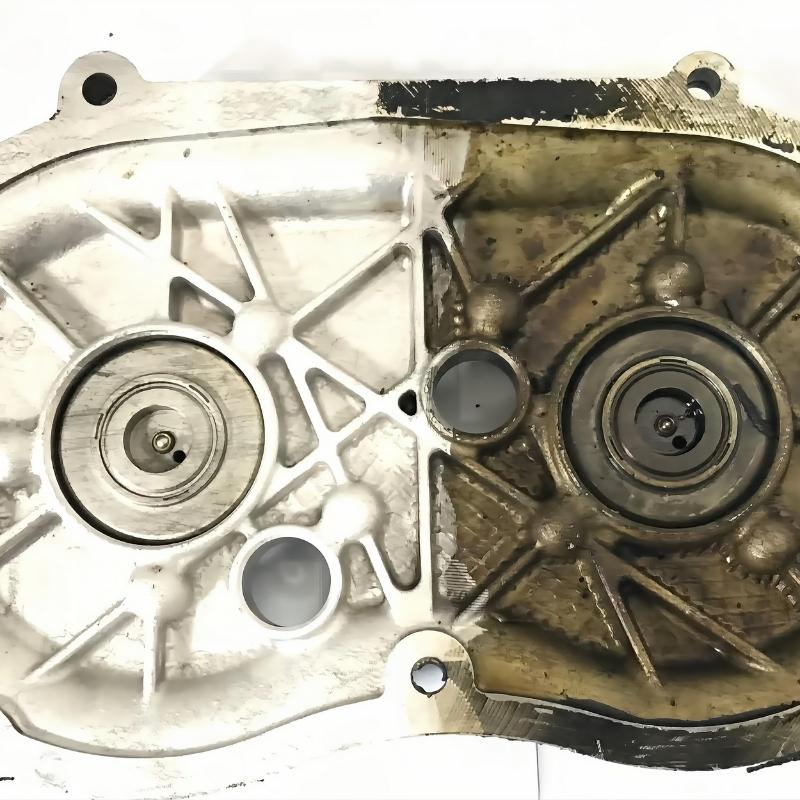

In industrial production, moulds are widely used, such as plastic moulds, tire moulds, auto blister moulds, and so on. And these mold applications always have a precise pattern, in the high temperature and high pressure production environment is easy to produce oxidation layer, deposition pollution and other problems, the traditional chemical cleaning, dry ice cleaning, the process is cumbersome, serious pollution. Laser cleaning machine cleaning mold efficient non-polluting does not hurt the precision of the mold.

With the chip process continues to miniaturize, the manufacturing difficulty of the PCB board is increasing, and the process is becoming more and more complex, maybe a hundred, maybe thousands of processes, after experiencing so many processes, the surface of the integrated circuit board will be more or less particle contamination, metal residues, organic residues, etc.. Traditional cleaning methods can not work, the laser cleaning machine’s non-contact non-thermal effect and non-injury characteristics, very suitable for PCB board cleaning

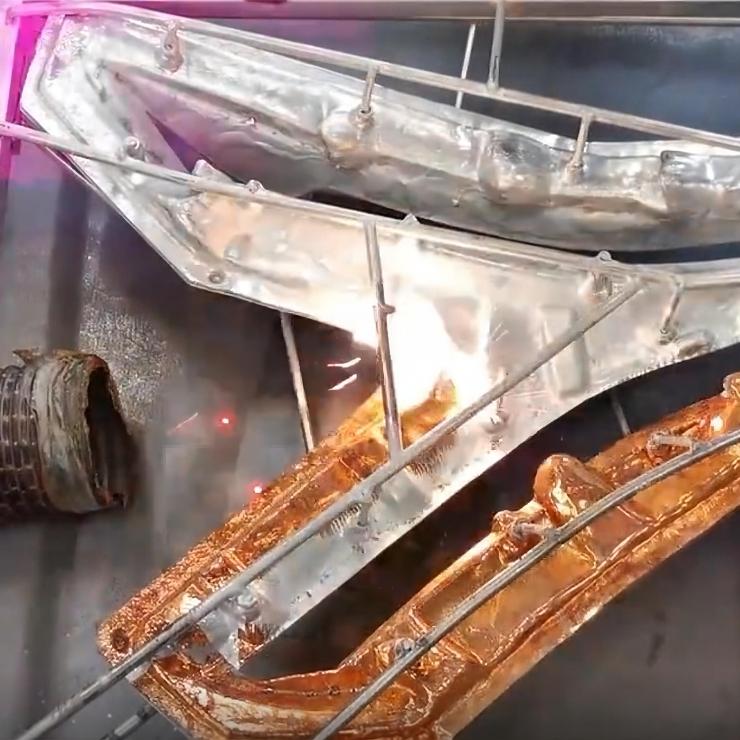

Industrial sheet metal fabricating and processing, generally will be painted on the metal surface to prevent rust and corrosion and increase the aesthetics, such as the industry, will give your car a beautiful paint, but once part of the paint is peeling or damaged, the paint needs to be repaired, the original old paint needs to be removed and then sprayed with new paint. This old paint removal way is sandpaper sanding time-consuming and dusty, with laser cleaning machine not only Less dust and high efficiency, does not hurt the base material.

After time, the surface of cultural relics and historical statues and stones will have a blackened oxidation layer that obscures their original splendor and beauty. If they are to be cleaned and washed, we are very careful, out of the principle of protection of cultural relics, they are ancient and fragile. If you use the pulse laser cleaning machine, you do not have to worry about the heritage itself will be damaged, no contact no thermal effect, is indeed one of the best choices for heritage cleaning.

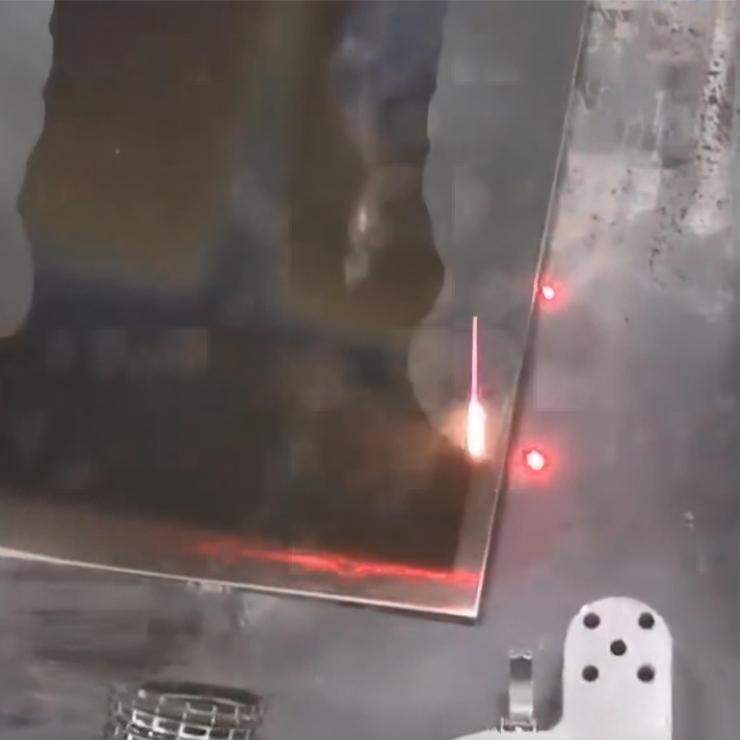

The traditional methods of metal rust removal are sandblasting, manual grinding and other methods, which have serious dust and air pollution and are very harmful to workers’ health. If laser cleaning equipment is used, the super power pulse laser will quickly remove the surface rust, basically no dust with the extraction fan to extract the dust, compared to the traditional mode will be more environmentally friendly and will not harm the health of workers.

Some Laser Cleaning Samples from Our Clients

- Samples

- Data Sheet

- Details

| PULSED LASER CLEANING PARAMETERS | ||||

| Laser Power(Pulsed Laser) | 50W | 100W | 100W | 200W |

| Model Number | MZ-50MINI | MZ-100MINI | MZ-100CP | MZ-200CP |

| Laser Pulse Width | 100NS | 100NS | 10-350NS | 10-350NS |

| Laser Wave Length | 1064um±5 | 1064um±5 | 1064um±5 | 1064um±5 |

| Laser Fiber Cable Length | 3M | 3M | 3M | 3M |

| Laser Power Adjustable Range | 10-100% | 10-100% | 10-100% | 10-100% |

| Fiber Laser Beam Quality | <1.6㎡ | <1.6㎡ | <1.6㎡ | <1.8㎡ |

| Single Pulse Energy | 0.8MJ | 1.1MJ | 1.1MJ | 1.5MJ |

| Pulse Laser Frequency | 45KHz | 45KHz | 20-2oooKHz | 20-2oooKHz |

| Power Supply | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz |

| Cooling Way | Air Cooling | Air Cooling | Air Cooling | Air Cooling |

| PULSED LASER CLEANING PARAMETERS | ||||

| Laser Power(Pulsed Laser) | 200W | 300W | 500W | 1000W |

| Model Number | MZ-200PW | MZ-300PW | MZ-500PW | MZ-1000PW |

| Laser Pulse Width | 90-130NS | 130-140NS | 130-160NS | 90-160NS |

| Laser Wave Length | 1064um±5 | 1064um±5 | 1064um±5 | 1064um±5 |

| Laser Fiber Cable Length | 5/10M | 5/10M | 10M | 15M |

| Laser Power Adjustable Range | 10-100% | 10-100% | 10-100% | 10-100% |

| Fiber Laser Beam Quality | <10㎡ | <10㎡ | <62.5㎡ | <62.5㎡ |

| Single Pulse Energy | 1oMJ | 12.5MJ | 25MJ | 45MJ |

| Pulse Laser Frequency | 10-5oKHz | 20-5oKHz | 10-5oKHz | 10-5oKHz |

| Power Supply | 220V/50Hz | 220V/50Hz | 220V/50Hz | 220V/50Hz |

| Cooling Way | Water Cooling | Water Cooling | Water Cooling | Water Cooling |

If you would like to know the efficiency parameters of the material you wanna clean, please contact us to request them, we have tested and obtained results for some materials

Related Product

Because of covid-19 we are temporarily unable to send engineers from our company to install the equipment, but we have a complete video and online installation assistance service.

Promise to deliver the machine within 7 days.

Please click on the specific model of the product, it will show the exact package size and weight, or you can call or email us directly for shipping information.

The pulsed fiber laser source is fully sealed for a lifetime of maintenance-free operation.

The only consumable item is the laser protection window.

Yes, this machine can be used not only can clean rust, oxidation, oil layer of metal material, but also for non-metal materials, like plastic, stone, wood, walls, tiles, etc.

All models of our laser cleaner use 220V/50hz power input.

And direct plug and play, no additional wiring required.

Generally speaking, if you want to sell our machines there, I have to evaluate whether you already have any experience with equipment sales, your after-sales team capability, marketing ability, etc.

Please get in touch with us for further negotiation.